Holistic Assurance and Verification

The automotive sector is characterized by progressively shorter development times and an increasing density of derivates. Also, the rising proportion of electronic components in vehicles leads to new and expanded demands for solutions in the field of vehicle, software and component tests. Formel D as an experienced partner of the automotive industry expertly maps these scopes of services in everyday virtual and real-life testing.

There is a demand for increasingly complex test and analysis methods in all phases of the vehicle lifecycle – from product development to production and aftersales. The experts decide individually in each case which method and means of testing is to be used. “Basically, the further a product has been developed, the more realistic are the test models we choose,” explains Marcel Klehr, Director Sales at Formel D. “In the run-up to each project, our detailed procedures are defined in close coordination with the customer. We are able to resort to well-founded know-how here.”

- Virtual prototype testing has an effect on all areas.

Involved From the Beginning

The system complexity in the vehicle structure has grown dynamically in the last few years, and this trend is continuing at present. In conjunction with considerably shortened development times until SOP (start of production), increasing global competition and rising material costs, this ensures that manufacturers go new ways and shift part of the test processes to the virtual level. Computer programs usually provide thousands of hours of testing and computation time nowadays, making an economically efficient development process possible.

Computer-assisted 3D CAD (computer aided engineering) programs are now a permanent, indispensable part of the complex development processes. Its field of application is virtually unlimited, and it includes aspects such as vehicle design, component arrangement and optimization of installation space. Right from the beginning of the development process, the engineers take potential costs resulting from material fatigue and wear into account.

Formel D supports customers in virtual installation tests and examines components and assemblies that potentially cause high costs. This is done in order to minimize the associated risk for the customer in the aftermarket. Here the experts resort to data from so-called digital mock-ups (DMUs for short). These are digital prototypes which replace cost-intensive physical prototypes (physical mock-ups) as far as possible. Realistic product simulation maps all relevant characteristics and functions and is a centrally controllable decision-making platform. “DMU-based tests link product development and aftersales,” Klehr explains. “Virtual prototype testing ultimately has an effect on all areas. For example, the positioning of a module in the engine compartment can be crucial for material demands such as weight, wall thickness and temperature resistance. This in turn leads to predictions of the runtime and ultimately of the aftermarket demand. Numerous factors come together at this point.” For this reason, it is of crucial importance to have a partner with a holistic view, for DMU tests allow competitive factors to be optimized early on in the development phase.

- Formel D supports numerous customers in the development and implementation of software-based assistance systems.

Reliable Safety Assistants

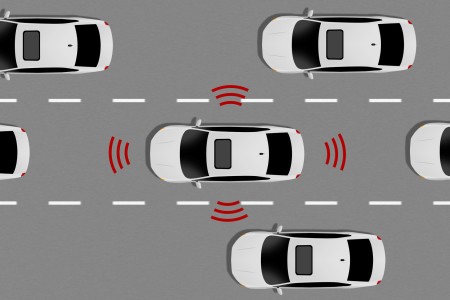

To relieve the driver in the increasingly demanding everyday traffic, manufacturers are developing more and more assistance systems for passenger cars. Many of these are based on data supplied by cameras and sensors installed in the vehicle. Even today, the precise, reliable functioning of these systems is a safety-relevant feature with high priority for OEMs and technology companies that supply components.

Formel D supports numerous customers in the development and implementation of software-based assistance systems. In order to organize the functions within the IT structure, today’s vehicle models are equipped with a network of different electronic control units – ECUs for short – on which the specific software runs in each case. Before flashing takes place, however, extensive detailed tests have to be conducted in order to ensure that the software is functioning perfectly. “In code review, we proceed via the ‘two pairs of eyes’ principle and analyze every detail of the source code, which contains the complex commands for the ECU,” says Klehr. “Software verification is carried out in several phases, partly at test facilities which simulate the interaction between different control units during flashing in a vehicle-specific way.” If discrepancies become evident in the course of the analysis, the IT experts derive the necessary corrective measures from them and directly implement them in coordination with the customer.

In the field of software as well as hardware, the virtual development phase is followed by real-life tests conducted in the complete vehicle. Formel D offers comprehensive support to its customers here too: from the camouflage of a prototype to professional test drivers and test centers equipped with state-of-the-art technology, the service portfolio includes individually scalable services. “An assistance system generates its added value through reliable functions. This is why we for example test camera-based sign recognition software and sensor-assisted distance warning systems in pre-series passenger cars. The fields of software and hardware verification automatically overlap here,” Klehr explains. “Our experienced test pilots follow detailed protocols worldwide during complex test drives, and this allows them to cover several test activities at the same time.” Depending on the individual requirements of the customer, the test scopes also include hardware tests of safety-relevant components in driving operation. These for example include belts and brakes, which have an immediate effect on the safety of passengers and other road users.

Support in the Aftersales Area

Besides safety-relevant functions, comfort-increasing features are in the focus of customer perception. They are therefore crucial for the overall qualitative impression and the resulting customer satisfaction. In the course of a vehicle lifecycle, numerous system updates are usually carried out in the context of service intervals. In this way, the software verification carried out during development also has an effect on aftersales processes. “Early on, while conducting the virtual tests in the development stage, we take the customer-specific characteristics of the IT architecture into account,” Klehr explains. “This is how we make sure that they match the existing system interfaces during later servicing.” Only a correctly functioning software allows complex flash processes of control units. The workshop updates data that can partly be experienced by the customer, that is, which offer an immediately innovatory character – such as new menu items in the case of navigation software. At the same time, system updates are an important factor for the functioning and value retention of a vehicle. Also, by allowing the driver to profit from them immediately, updates of this kind ensure his long-term satisfaction even after the purchase, and they also strengthen his brand loyalty.